Fibrillated raffia

The fibrillation consists in the controlled weakening of the flat raffia. This process involves the creation of small repeated cuts at a constant distance, creating a homogeneous texture in the fiber. Thanks to this process, the fibrillated raffia is more workable and has a soft feel.

One of the problems that can be found with fibrillated raffia is to have a large amount of dust during processing. CalloniFIL, thanks to the selection of excellent raw materials and careful processing, is able to obtain a yarn that generates a minimum amount of dust during the processing of our customers. This makes it possible to reduce machine stops for cleaning, as well as having greater safety at work.

Yarn technical characteristics - Fibrillated raffia

| UM | Polypropylene | Polyethylene | Bio-Plastic | |

| Title | [Td] | 500 - 12.000 | 500 - 12.000 | 2.000 - 16.000 |

| Tenacity | [g/Td] | 3,5 - 5,5 | 3,2 - 4,8 | 0,5 - 1,1 |

| Elongation | [%] | 8 - 17 | 16 - 35 | 28 - 41 |

The width and thickness of the yarn are built upon customer's request, based on the final application of the product. The application ranges are:

| Minimum | Maximum | |

| Width | 1,9 mm | 11,0 mm |

| Thickness | 20 µm | 87 µm |

For each yarn, it is possible to add customized additives and colors. The treatments offered are:

- UV resistance

- Lubrication

- Decreased residual electrostatic current

- Flame resistance

- Slippery treatments

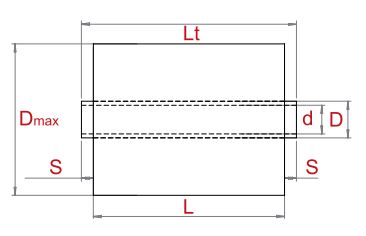

Spool technical features

| Measurement | Sezione | Description | Std value [mm] |

| d | Tube | Tube internal diameter | 90 + 2 |

| D | Tube | Tube outside diameter | 100 + 2 |

| Lt | Tube | Tube length | 260 + 2 |

| Dmax | Spool | Maximum spool diameter | 300 + 10 |

| L | Spool | Winding running | 250 + 10 |

By performing the winding service, it is possible to have tube and spool dimensions customized according to your needs. The values shown in the table refer to a standard product and are not exhaustive of the possible combinations. Contact us to evaluate each request.

Packaging technical features

In order to preserve the integrity of the spools, great care is taken in the final packaging. Each spool is covered with a protective film, the shelves are firm and the external coating is resistant to chafing and rain. The productions are tracked and each spool is associated with a production lot in order to guarantee complete traceability throughout the supply chain.

All the raw materials are chosen with great care and comply with the regulations in force in the technical-food field. The variety of items offered, experience in the sector, the ability to satisfy every need and constant attention to specific production techniques put us in a position to satisfy our customers by defining customized solutions.